Loading Dock Automation: The Complete Guide for Facility and Logistics Managers

Loading docks are the operational heartbeat of commercial buildings, warehouses, and logistics hubs. Every delivery, every dispatch, and every compliance check flows through the dock. When these processes run manually — paper-based booking logs, guards checking IDs, phone calls to confirm arrivals — they become a source of constant inefficiency, cost, and risk. This guide covers what loading dock automation actually involves, how it works in practice, and why more facility and logistics managers are making the switch to automated systems.

What is loading dock automation?

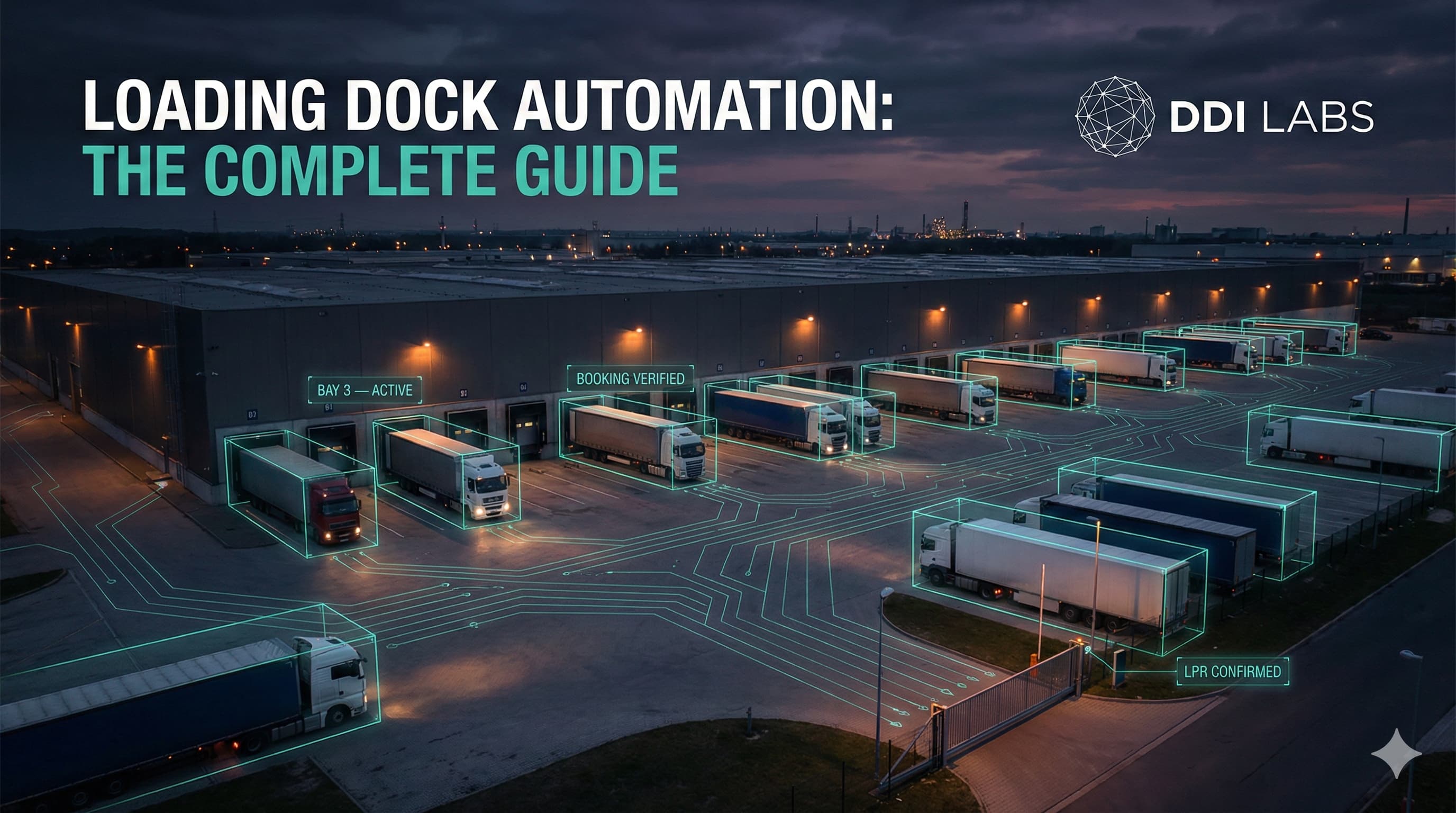

Loading dock automation is the use of technology — specifically AI-powered cameras, licence plate recognition (LPR), online booking software, and automated gate or barrier controls — to manage the full delivery cycle without manual checks at each step. Instead of a dockmaster verifying every vehicle by hand, the system handles booking confirmation, vehicle identification, gate operation, bay assignment, occupancy monitoring, and departure logging automatically.

This contrasts sharply with traditional manual processes, where each delivery requires a staff member to confirm the booking, check driver credentials, raise the barrier, monitor the bay, and record the event. In high-volume facilities handling hundreds of deliveries per day, these manual steps add up to significant labour costs, delays, and data gaps.

How does loading dock automation work?

A fully automated loading dock follows a structured flow from booking to departure. Here is how a typical delivery cycle works with DDI Labs' dock automation platform:

- Online booking: The driver or logistics coordinator books a delivery slot in advance through the online booking portal. The booking captures vehicle details, delivery time, bay preference, and any special requirements.

- Arrival and LPR verification: When the vehicle arrives at the dock entry, a licence plate recognition camera reads the plate and cross-checks it against the booking database in real time.

- Automatic gate operation: If the vehicle is verified, the gate or barrier opens automatically. Unregistered or non-booked vehicles are held and flagged for review.

- Bay assignment and tracking: AI cameras track the vehicle from entry to its assigned bay, monitoring occupancy status in real time across all bays.

- Anomaly detection: The system generates instant alerts for overheight vehicles, overstays, unregistered plates, or blocked bays — sent directly to the dock manager's dashboard or mobile device.

- Automated departure: When the vehicle leaves the bay and exits, the camera confirms departure, and the booking is closed automatically with a complete timestamped record.

The entire process runs with minimal human intervention. Staff are only engaged when the system flags an exception that requires a decision.

Key features to look for in dock automation software

Not all dock automation platforms are built equally. When evaluating solutions, look for these core features:

- Real-time dashboard: A centralised, cloud-based interface showing live bay status, vehicle tracking, alerts, and booking activity.

- LPR integration: High-accuracy licence plate recognition that works across plate types, lighting conditions, and vehicle sizes.

- Booking management: An online portal for drivers and coordinators to create, modify, and cancel bookings — reducing phone calls and manual scheduling.

- API connectivity: Integration with existing warehouse management systems (WMS), enterprise resource planning (ERP), and building management platforms.

- Overstay and anomaly alerts: Automated notifications when vehicles exceed their booked time, enter without a booking, or breach height restrictions.

- Compliance reporting: Automatic generation of audit trails and compliance reports with timestamps and images for every dock event.

- Driver kiosk support: On-site kiosks that guide drivers through check-in, provide bay directions, and confirm booking details on arrival.

Loading dock automation vs. loading dock management software — what's the difference?

These terms are often used interchangeably, but they describe different levels of capability. Loading dock management software typically focuses on scheduling — allowing staff to create and manage delivery bookings, assign bays, and view a calendar of upcoming deliveries. The key word is manage: humans still operate the process at every step.

Loading dock automation takes this further. It doesn't just schedule — it executes. The system verifies vehicles, opens gates, tracks bay occupancy, detects anomalies, and logs departures without requiring a person to act at each stage. The shift is from a managed workflow to a self-operating system, where human involvement is limited to exception handling and oversight.

ROI and cost savings

The financial case for loading dock automation is driven by several measurable outcomes:

- Reduced guard and dockmaster hours: Automated verification and gate operation eliminate the need for dedicated staff at dock entry points during standard operations.

- Fewer compliance penalties: Real-time monitoring and automatic audit trails reduce the risk of non-compliance with Chain of Responsibility (CoR) and OH&S regulations.

- Faster turnaround per delivery: Manual verification typically takes three to four minutes per vehicle. Automated LPR-based verification completes in under 30 seconds, dramatically increasing throughput.

- Improved data accuracy: Every event is logged automatically with timestamps and images, eliminating data entry errors and providing reliable records for auditing.

As a reference point, the International Towers Barangaroo deployment — managing over 350 daily deliveries — achieved full ROI within 18 months of going live. The primary savings came from reduced labour costs and the elimination of manual booking errors.

Is loading dock automation right for your facility?

Loading dock automation delivers the greatest value for facilities that meet one or more of the following criteria:

- High delivery volumes: Sites handling 50 or more deliveries per day, where manual processes create bottlenecks and labour costs.

- Multi-tenancy buildings: Commercial or mixed-use properties where multiple tenants share dock facilities and coordination is complex.

- Cold chain or time-sensitive logistics: Operations where delivery timing is critical and delays have direct financial or quality impacts.

- Strict compliance requirements: Sites subject to Chain of Responsibility, OH&S, or other regulatory frameworks where accurate records and real-time monitoring are mandatory.

If your facility matches any of these profiles, loading dock automation can significantly reduce costs, improve throughput, and strengthen compliance.

Ready to automate your loading dock?

Learn how DDI Labs' AI-powered dock automation platform can streamline your delivery operations. Book a demo to see the system in action.

Learn More Book a DemoLooking for more information?

Check out our dedicated solution pages for more details on how we can help your business.

Interested in Our Solutions?

Contact us today to learn how our smart tools can help your business improve safety and compliance.

Book a Demo